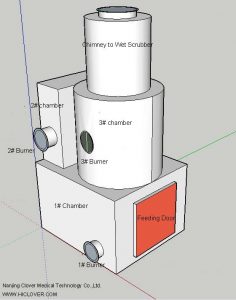

Would this mean that the plant would operate only 12 hours per day? Normally operating the station 24 hours per day should be able to valorize 12 tons per day for an installation with a capacity of 500 kgs/hr. Would plant operations be operational on a basis of 24 hours per day, 7 days a week, all year long except for regular and preventive maintenance periods? How many hours per year could your process be operational? What would be your approach for larger projects aiming to valorize 1 000 tons per day? How much electricity could be produced using you technology based on a 1 000 tons per day installation to valorize urban wastes having a humidity factor of say 50% and a calorific value in the order of 2.5 MW/ton of wastes at the entrance of the waste-to-energy station (i.e. before pre-treatment of wastes)? What volume and characteristics of ashes would be produced from such solid wastes valorization? What would be the capital cost necessary to meet the requirement to valorize 1 000 tons per day of urban wastes? What would be the selling price of electricity per kWhour to meet targeted profitability? Could you valorize sludge volumes coming from sewage treatment plants and if so at what maximum humidity factor could you operate the station at? Considering that your process is an incineration process, oxygen will be required, therefore there will be some air emissions from the process, how can air emissions be controlled to meet environmental norms? What would be your implication in any project : would you prepare process engineering, electricity production engineering, engineering for site work, buildings, electrical hook up to existing electrical network? Do you have complete construction capabilities or would you require a local partner to carry out which portion of construction work? Would you also operate the station or use a local partner to operate the station? Can you quote a custom design that can accommodate this container size? What′s the MIN and MAX chamber temperature and its heating time from MIN to MAX temperature? Do you also manufacture the afterburner? How about the exhaust pipe?